Washer Calculator Tools

*It is ultimately user’s responsibility to determine product suitability. Solon Manufacturing Co. is not responsible for product that is ordered incorrectly, misused, or misapplied. Contact a Solon engineer for recommended guidelines for product use.

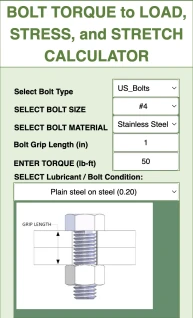

Bolt Torque Calculator

Our Bolt Torque to Load, Stress, and Stretch Calculator is designed to simplify complex engineering calculations for bolt fasteners. By inputting essential details such as bolt type, size, material, grip length, and applied torque, this tool provides precise outputs.

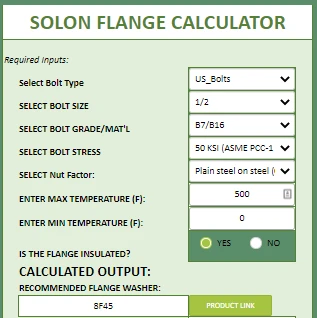

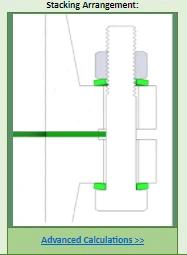

Flange Leak Prevention Calculator

Minimize bolt load loss and prevent flange leaks. Quickly design a live loading system for flange applications. Fill out the form to access the flange leak prevention calculator.

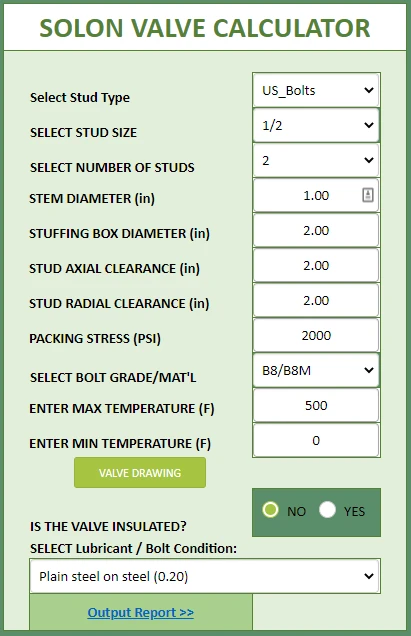

Valve Leak Prevention Calculator

Reduce fugitive emissions and valve leaks with optimized solutions designed to increase the value of the live loading system. Fill out the form to access the valve leak prevention calculator.

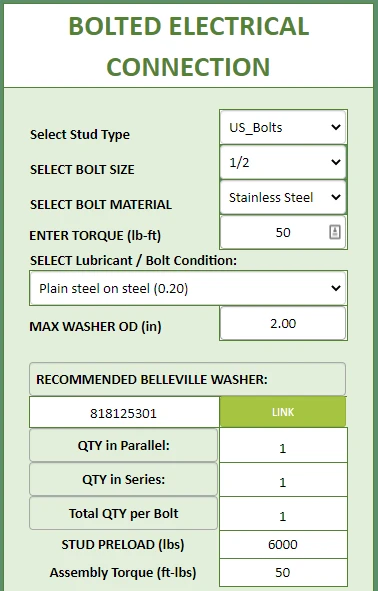

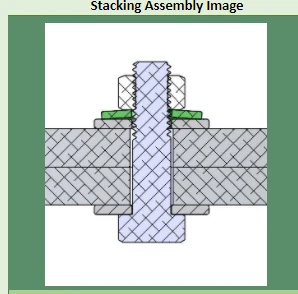

Bolted Electrical Connections Calculator

Maintain bolt preload and keep bolted joints tight with Belleville springs & washers installed on the bolted connections within your electrical assembly. Fill out the form to access our bolted electrical connections calculator.

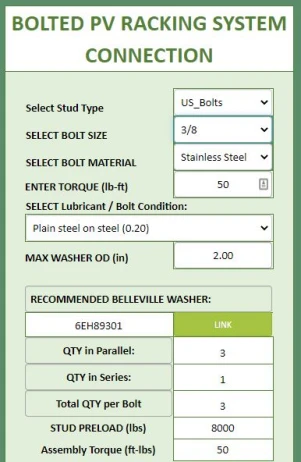

PV Racking Systems Calculator

Ensure the integrity of your solar photovoltaic (PV) racking systems by installing Solon Belleville Springs & Washers to the bolted electrical and ground connections that are subject to loosening and developing elevated resistance. Solon Manufacturing Co. has designed an interactive web tool to help select the proper washer products necessary to maintain the bolt preload on the connections. Fill out the form to access our washer selection tool for solar PV structural assemblies.

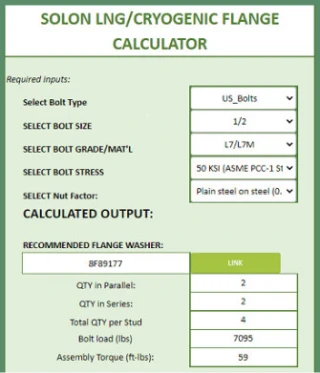

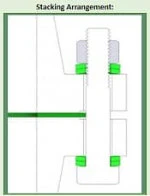

LNG /Cryogenic Flange Calculator

Reduce process leaks and fugitive emissions in liquefied natural gas (LNG) and cryogenic applications were cold temperatures and corrosion are factors. Fill out the form to access the LNG / cryogenic flange calculator.

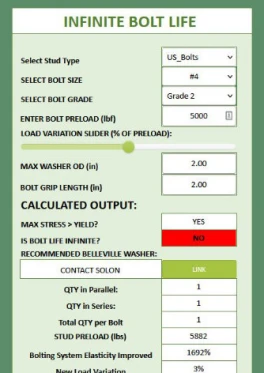

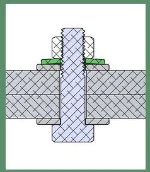

Infinite Bolt Fatigue Life Calculator

Increase the elasticity of the fastening system, improve cycle life of the bolt, and eliminate the risk of fatigue failure. Fill out the form to access the infinite bolt fatigue life calculator.

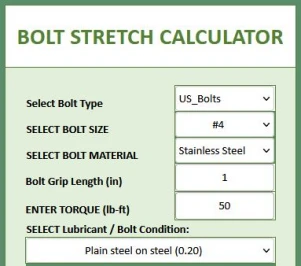

Bolt Stretch Calculator

Bolt stretch is an important factor in the retention of preload. As torque is applied to a bolt, the stress on the bolt increases. This stress results in bolt stretch that is proportional to stress and active bolt length (or grip length). Fill out the form to access the bolt stretch calculator.

Contact Us