Industrial Spring Washer Capabilities

Solon industrial spring washers achieve optimally tight connections in gasket and packing applications and are self-damping with long service life. We leverage our design and engineering experience to manufacture washers from industry standard and exotic material options. Solon’s washers maintain tight bolt connections and maintain bolt preload to reduce bolted joint failures.

Washer Ordering Options

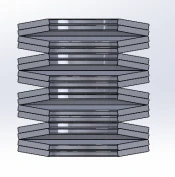

Washers can be ordered individually or

stacked in series, parallel, or combination configurations. We carry both

imperial and

metric sizes.

Need assistance determining which

washers, washer sizes or quantities are right for you? Visit Solon’s

washer calculator tools to inform your purchase.

Advantages of Industry-Specific Washers for OEM’s, Distributors & More

Industrial washers achieve optimal connections and are highly configurable to be used with—and extend the lifespan of—hardware and other industrial components. In addition to withstanding extreme

vibration,

differential thermal expansion,

bolt creep and yield, and

relaxation, our washers can form a reliable connection and yield value-added benefits such as:

- Corrosion Resistance

- Improved Joint Integrity

- Prevent Tension Loss

- Leak Prevention

- Enhanced Stability and Flexibility

- Reduce Fugitive Emissions

- Prevent Arc Flash Hot Spots

- Maintain Bolt Integrity

Spring Washer Solutions for Industrial Bolting

Since 1949, Solon Manufacturing Co. makes bolting better through the engineering and manufacturing of Belleville spring washers for industrial bolting applications worldwide. We manufacture our Belleville washers in a variety of

materials and finishes to meet your requirements for temperature range, corrosion resistance, and yield strength. Visit our industry pages to learn more about Belleville washer applications.

General Purpose Bolting

Use

Belleville spring washers to prevent stress caused by vibration and mechanical movement in a range of bolting applications.

General-purpose industries include packaging, automation, machinery, manufacturing, and entertainment.

Commercial Applications

Commercial Applications include heavy equipment, packaging, aerospace, manufacturing, transportation, pulp and paper, and medical.

Electrical Connections

Use

Solon Disc Springs and

Belleville Spring Washers to maintain bolted

electrical connections and prevent hot spots that lead to arc flash or catastrophic failure.

Valve Live Loading

Valve Live Loading: Prevent valve leaks that lead to fugitive emissions with

Solon Flange Washers.

Cryogenic Flange Live Loading

Use cold temperature-resistant flange washers for valve live loading applications in

cryogenic environments.

Elevated Temperature Flange Live Loading

Elevated Temperature Flange Live Loading: High temperatures and thermal cycling cause stress on flange joints. Prevent tension loss and fugitive emissions with

Solon Flange Washers.

Structural Bolting

Belleville springs provide stability and flexibility required to ensure joint integrity in

structural applications.

Environmental Bolting

Corrosion and weather-resistant

Solon Flange Washers maintain bolt integrity in natural and

artificial environments involving corrosive substances.

High Cycle Applications

High Cycle Applications: Use

DIN/Disc springs in high-cycle applications where there are issues with fatigue and changes in stress.

Contact Solon For Application-Specific Springs & Washers

Contact us to discuss recommendations suitable for your application or view our

Washer calculator tools to assist with your fastening system design.