Washers For Hydrogen Fuel Cells Stacks

Browse our washer products online, including our Belleville Springs, DIN & Disc springs, Flange Washers and more or speak to our experienced design/engineering team and let us find a solution for your spring & washer needs.

Hydrogen Fuel Cell Washer Design Considerations

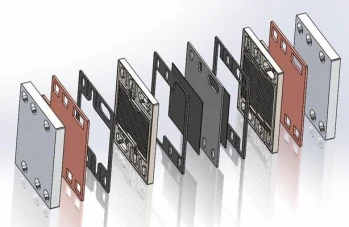

PEMs use hydrogen fuel and oxygen from the air to produce electricity. The Membrane Electrode Assembly (MEA) is an assembled stack of PEM, a catalytic layer, and a Gas Diffusion Layer (GDL) that separates bipolar plates and gasket layers to produce a desired electrical output. The entire stack is commonly loaded with tie rods/studs for optimal clamping pressure.There are many spring designs and stacking arrangements that can be used for a fuel cell application. Our engineering team can help design the most cost-effective Belleville spring stack solution to meet your requirements.

Hydrogen Fuel Cell Clamping Pressure Factors

Clamping force/pressure, or tightening torque, has an impact on the performance of PEM fuel cells and can be impacted by several factors, including:- Insufficient clamping force may result in leakage of the assembly.

- Reduced clamping force results in increased contact resistance between the GDL and the bipolar plates and this reduces cell performance.

- Excessive clamping force may reduce porosity of the GDL and reduce the flow of gas and liquid that can compromise cell performance.

- Excessive clamping force may mechanically damage components of the cell.

Solon Belleville Spring & Washer Advantages

Solon Belleville Springs can be assembled onto tie rods to maintain optimal pressure on the fuel cell to not only prevent failures in the form of leaks or damage, but they can also improve the overall performance of the fuel cell. There are many spring designs and stacking arrangements that can be used for a fuel cell application. Our engineering team can help design the most cost-effective Belleville spring stack solution to meet your requirements.- Reduce bolted joint failures

- Maintain bolt preload under normal conditions

- High spring force with small deflections

- Absorbs shock and compensates for vibration

- Predictable load-deflection curves where straight, progressive or regressive characteristics are required

- No deformation or fatigue under normal conditions

Solon Washers For Fuel Cell Stacks

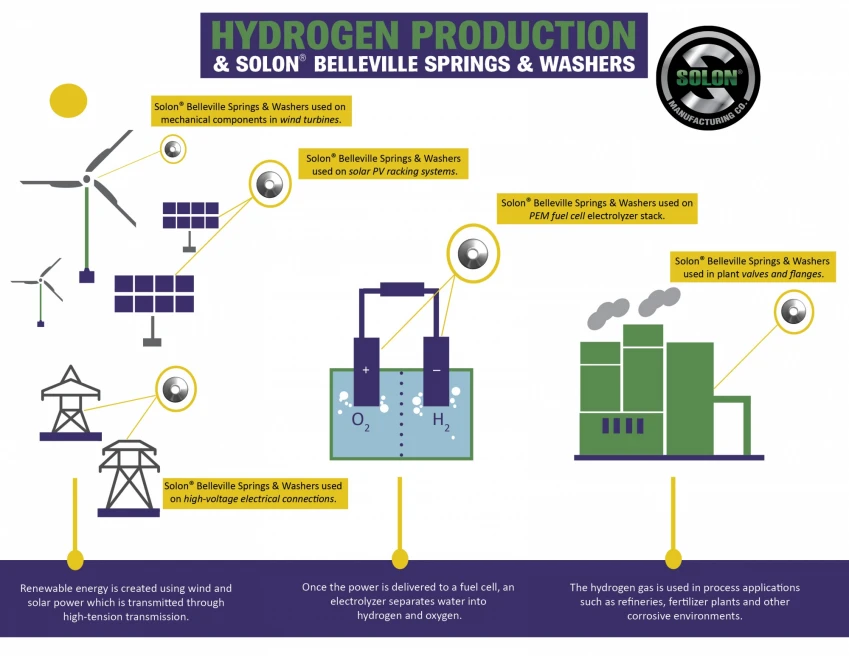

With industry-standard and exotic material options, Solon Manufacturing provides a washer solution for every requirement. Additionally, Solon Manufacturing Co. is proud to contribute to the renewable energy industry by manufacturing washer products for hydrogen technologies and similar industries dedicated to reducing carbon dioxide emissions. Our spring and washer products are designed to optimize the performance of your fuel cell stacks while contributing to sustainable, future-focused energy industries.Contact a Solon Expert Today

Contact our design and engineering team with any questions you might have regarding your hydrogen fuel cell stack or additional inquiries.Learn more about the use of our products in the renewable energy industry:

White Paper: Using Belleville Springs to Meet ASME Boiler and Vessel CodeOther ways Solon Belleville Springs & Washers are used in the renewable energy industry:

- Mechanical components in wind turbines

- High-voltage electrical connections

- Solar PV racking systems

- PEM fuel cells

- Valves and flanges