Commercial Bolting Applications For Belleville Spring Washers

Bulk Belleville Spring Washers For the Commercial Industry

Belleville spring washers are conical shaped discs that are designed to deflect at a given rate and produce large loads in a very small space. Solon Manufacturing Co. is your premier supplier of bulk Belleville Washers for commercial bolting applications. Our Belleville springs maintain bolt preload by preventing bolt tension loss caused by vibration, relaxation, thermal expansion, and high-temperature yield. Solon’s Belleville springs are known for their long service life, self-dampening capabilities and compact design for use in virtually any commercial bolting application. We supply high-volume orders of imperial or metric ISO 9001: 2015-certified Belleville washers with quick turnaround times.

Browse our washer products below, Contact us for more information about using commercial purpose washers.

Commercial Bolting Applications by Industry

Solon’s industrial spring washer solutions include Belleville Washers, Flat Washers, Flange Washers and DIN/disc springs that can be used in single or stacked variations, depending on the load and level of deflection your application requires.Heavy Agricultural Equipment Bolting

Our Belleville washers maintain bolted connections that hold up to the harsh weather conditions of heavy Agricultural equipment bolting applications. Solon considers agricultural safety and quality prerequisites to manufacture Belleville washers that satisfy explosion-proof and temperature-sensitive requirements in atmospheres with high particulates.- Applications: Tractors, combine harvesters, grain elevator conveyors, flour and feed milling machines, spice-grinding plant machinery and sugar processing equipment.

Commercial Packaging Equipment

Packaging Equipment requires washers that hold up to machinery that operates at high speeds and generates high levels of vibration. We offer compact Flat Washers, Flange Washers and DIN/disc springs that reduce joint failure, equipment downtime and achieve high load capacity.- Applications: Plastic Packaging Machinery, Thermoforming Machines, Blister Packaging Machinery and Paper Box Machines.

Aviation/Aerospace

Solon Manufacturing offers various styles of aviation/aerospace washers in flat and stackable spring styles that maintain bolt load and torque on bolted connections used to secure propellors onto aircraft.- Applications: We provide aerospace spring washer solutions for CATTO propellors and additional equipment in materials and finishes that meet stringent aerospace specifications.

Manufacturing

Our manufacturing washers maintain bolt preload to prevent loosening and subsequent bolt failure to withstand the day-to-day rigors of production and manufacturing process design. These ISO 9001:2015 certified washer products are designed to meet the needs of all facets of manufacturing and production design processes.- Applications: Manufacturing washers can be used with bolts, studs, nuts, gaskets and other hardware in:

- Electric motors

- Stamping die strippers

- Clamping systems

- MRI equipment, x-ray machines

- Rolling Mills

- Braking systems for surgical tables and hospital beds

- CNC tool changer

Transportation

Solon’s transportation washer products are proven to maintain bolt preload under severe conditions such as displacements of rail joints, frog crossings, and turnouts.- Applications: Railroad Tracks, Tank Cars, Railroad Ties, Bogies, Coupling Devices, Brake Systems.

Pulp & Paper

Belleville springs and washers to reduce mechanical stress and maintain bolt preload in pulp and paper processing equipment.- Applications: Paper Machines, Pumps, Pulp Equipment.

Medical Equipment

Solon Manufacturing manufactures reliable solutions to medical equipment washer options that adhere to stringent medical quality, regulatory standards and cleanroom needs.- Applications: Moveable Medical Equipment, X-Ray Machines, Hospital Equipment and Pharmaceutical Equipment.

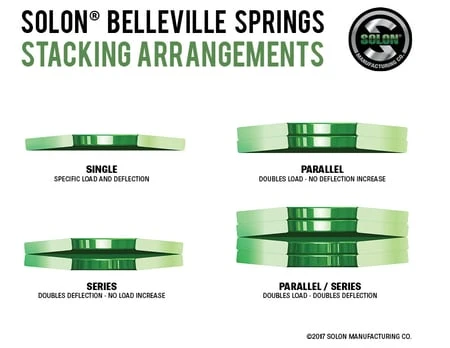

Custom Commercial Bolting Belleville Washer Stacking Arrangements

Solon’s stacking arrangements for Belleville Washers, Flat Washers, Flange Washers and DIN/disc springs include:

Single – For specific load and deflection.

Parallel – Doubles load capacity with no deflection increase.

Series – Doubles deflection with no load increase.

Series Parallel – Doubles load and doubles deflection.

Additional Resources for Commercial Washers

Belleville springs are available as standard metric sizes from 4mm-80mm. Belleville springs are available as standard Imperial sizes from 7/64” to 2-1/2” ID.Technical White Paper: Using Belleville Springs to Maintain Bolt Preload

Video: Solon Belleville Spring Washers

Data sheets and calculators