Industrial Belleville Spring and Washer Manufacturer

Belleville springs and washers are highly configurable products that are used in conjunction with complementary hardware (bolts/studs and nuts) as well as other industrial components, such as gaskets and packing material to achieve an optimally tight connection where high spring loads are desired.

Keep Bolted Joints Tight Using Solon's Belleville Springs & Washers

Bolted joints loosen due to a variety of reasons. The loss of bolt preload is one of the most prevalent. Solon Belleville Springs & Washers reduce bolted joint failures by maintaining the bolt preload. They are particularly useful where vibration, differential thermal expansion, relaxation and bolt creep, and bolt yield are problematic.

Solon Belleville Spring & Washer Advantages

- Maintain bolt preload under normal conditions

- High spring force with small deflections

- Absorbs shock and compensates for vibration

- Predictable load-deflection curves where straight, progressive or regressive characteristics are required

- No deformation or fatigue under normal conditions

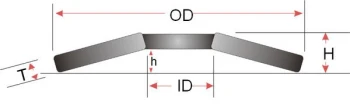

Typical Belleville Spring Diagram

Choosing a Solon Belleville Spring & Washer

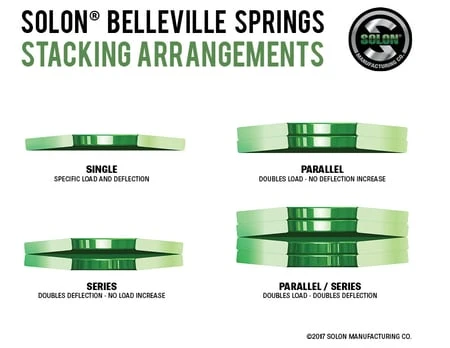

Belleville springs and washers are used in a variety of applications across virtually every industry that maintains bolted connections. The washer is not an insignificant engineering contribution—by combining washers in stacks or series or including them in other bolt assemblies, longer service life, lower maintenance and high levels of equipment dependability and safety are realized. Solon offers thousands of catalog washer options—sizes ranging from #4 screw to 4 inches available in both Imperial and metric sizes. With industry-standard and exotic material options, Solon Manufacturing provides a washer solution for every requirement. Our vertically-integrated approach to manufacturing makes Solon custom-friendly. Submit your drawing or contact an application engineer to discuss your needs.

Considerations for Selecting a Belleville Spring or Washer Product

- ID

- OD

- Stacking constraints

- Load

- Bolt size

- Bolt material

- Temperature

- Environment

- Application

- Size constraints

- Aim preload

Contact Solon Manufacturing for Belleville, DIN & Disc Spring, and Flange Washers

Contact us for more information regarding our Belleville disc spring and DIN washers, or request a quote for further pricing details today. Solon Manufacturing is your trusted source for a wide range of Belleville washers.

Solon Belleville Springs & Washer Resources

Download our Belleville Springs catalog or the Belleville Springs Data Sheet to assist with the selection of a suitable product for your requirement.